HARDFACING TC

HARDFACING TC

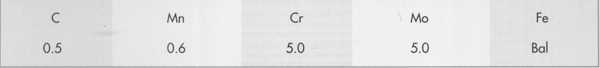

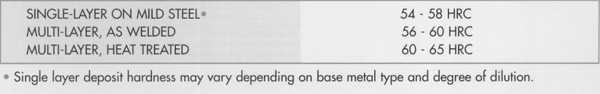

Descirption and HARDFACING TC is an exceptionally smooth running, AC/DC electrode depositing air hardening, high speed tool steel metal. The C-Cr-Mo deposit combines toughness and wear resistance with full hardness being retained at temperatures between 500C and 600C. HARDFACING TC is used on a wide range of applications involving the repair and manufacture of punches, dies, shear blades, lathe tools, forming rolls and cutting edges etc. When welding on hardened tool steel preheat and stringer beads are recommended. Deposit Properties The hard tough HARDFACING TC welding deposit may be annelaed by soaking at 800C and then furnace cooled. To re-harden the deposit, heat slowly to 850C and then quickly to 1250C, soak for 15 minutes and quench in oil or an air blast if component is small. To develop full hardness, temper at 520C for a one hour period.

Applications