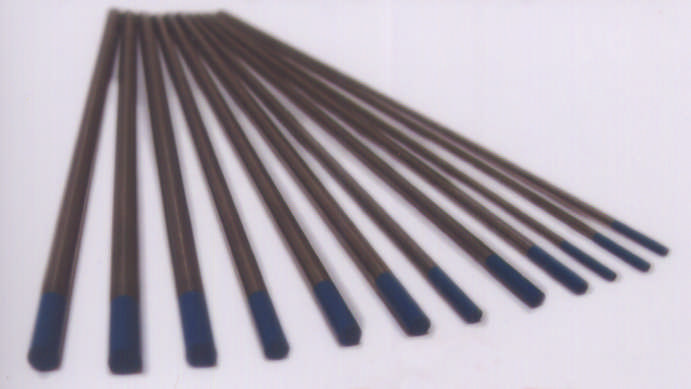

STAINARC 312

STAINARC 312

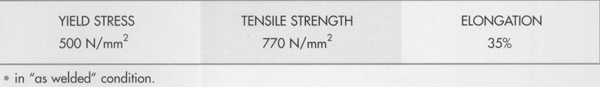

Description and STAINARC 312 is a rutile type electrode employing a stainless steel core wire and deposition a 29% Cr - 9% Ni stainless steel filler metal for the high strength welding of a wide range of alloy steels and dissimilar ferrous metals. The high ferrite, austenitic stainless deposit has excellent resistance to hat cracking even under conditions of high dilution of carbon steels, alloy and die steels and cast irons. STAINARC 312 is a universal maintenance electrode combining high strength, toughness, wear and corrosion resistance with compatibility to all ferrous metals. STAINARC 312 has many diverse applications in numerous engineering fields. It is an ideal electrode for the high strength welding of medium-to-high carbon steels, low alloy hardenable steels and dissimilar ferrous metal combinations. In general maintenance and repair situations, STAINARC 312 is also suitable for use a buffer or intermediate layer where hard surfacing deposits are applied in depth.

Applications