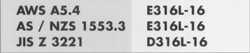

STAINARC 316L

STAINARC 316L

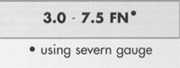

Description and New generation STAINARC 316L is an extra low carbon, rutile type electrode exhibiting superior all positional (except vertical down) performance with an improved moisture resistant coating for weld metal of high radiographics integrity. The smooth arc action of STAINARC 316L - 16 together with low spatter and excellent slag control / detachability promote exceptional weld appearance and profile. Other features include high arc stability and easy restriking. STAINARC 316L deposists Molybdenum bearing, 19 Cr / 12 Ni / 2.3 Mo filler metal to meet the requirements for welding AISI type 316 and 316L stainless steel in critical applications. STAINARC 316L is also recommended for the general purpose welding of common 300 series stainless steels such as 301, 302, 304 and 304L. It is also suitable for the general welding of ferritic stainless alloys such as 3 Cr 12.

Applications