HARDFACING ARC 9 (Formely Hardfacing AB 10)

HARDFACING ARC 9 (Formely Hardfacing AB 10)

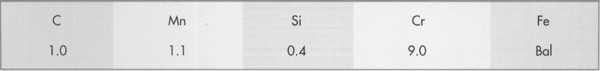

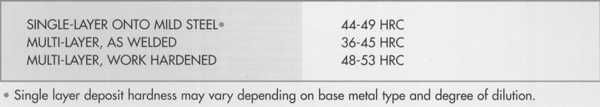

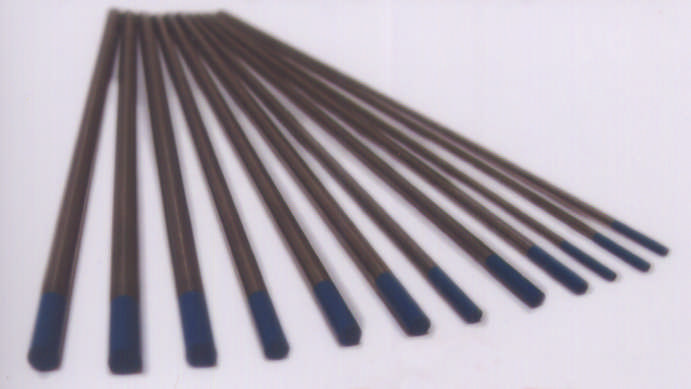

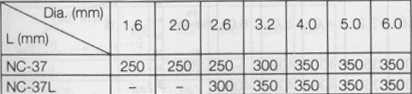

Description and HARDFACING ARC 9 is a basic coated, AC / DC electrode for general purpose hard surfacing applications on carbon or austenitic manganese steels. This electrode deposits a tough, semi-austenitic C-Cr-Mn alloy capable of withstanding heavy gouging abrosian and impact. Typical applications include rebuilding or overlay of crusher jaws, rolls, cones, hammers, tractor grousers, dozer blades, rippers and conveyor chains. When welding on high carbon steels and alloy steels of high hardenability, preheat is recommended or alternatively a "buffer" layer of STABLEARC 18 or 16 may be used with a lower preheat temperature. Deposit Properties HARDFACING ARC 9 deposits a tough, semi-austenitic, C-Cr-Mn hard surfacing alloy which is air hardenable and can be work hardened to give a wear resistant surface to withstand heavy impact and gouging abrasion.

Applications